When it comes to 3D printing, ABS has earned its stripes as a go-to material for those seeking durability and heat resistance. If you’re an enthusiast or a professional looking to make strong 3D-printed parts that can withstand the rigors of the real world, then ABS 3D printers are your best bet. And let’s face it, when you’re pouring hours and creativity into a project, the last thing you want is for it to crumble at the sight of a heat lamp.

The Appeal of ABS Filament

ABS filament is like the superhero of the 3D printing world. It’s known for its strength and ability to withstand higher temperatures compared to its cousin PLA. This makes it an ideal choice for projects that need to be both tough and heat-resistant, from automotive parts to engineering-grade prototypes. It’s not just about strength; it’s also about durability. ABS is less likely to shatter or crack under pressure, so it’s your go-to when making items that have to stand the test of time—or at least the test of your kids’ toy box.

FDM Printing: The Best Way to Go

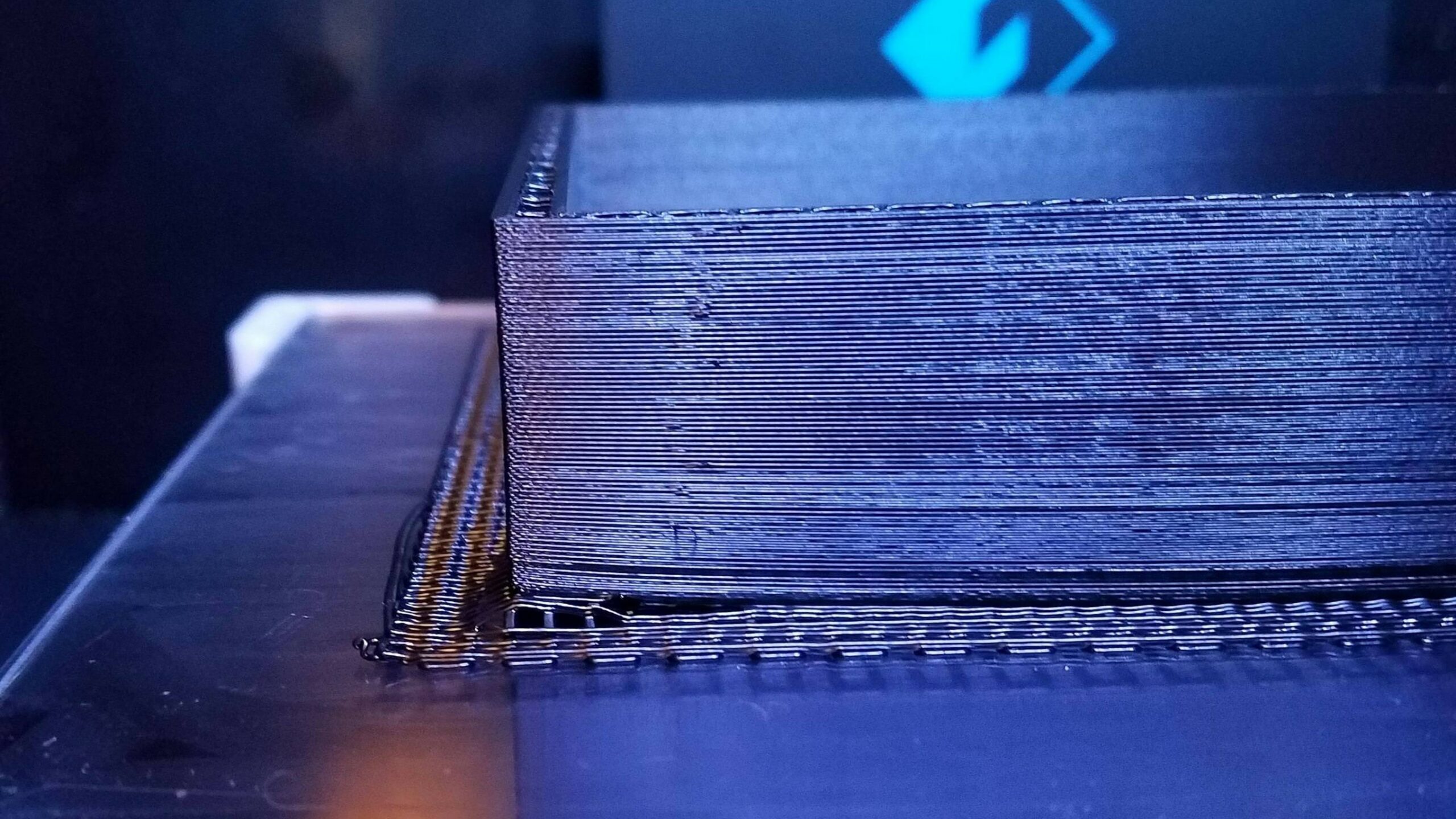

FDM, or Fused Deposition Modeling, is the most common method for printing with ABS filament. It involves melting the filament and layering it to create your masterpiece. The kicker here is the temperature. ABS requires a hotter environment to print effectively, usually in the ballpark of 230 to 250 degrees Celsius. This makes an enclosed 3D printer almost a necessity to keep the temperature stable and prevent warping, which is the bane of any ABS printer’s existence.

Warping Prevention: A Must-Know Skill

Speaking of warping, let’s dive into that. Warping is basically when the corners of your print start curling up, ruining what could have been a beautiful creation. It’s like baking a cake only to have it sink in the middle. An enclosed 3D printer is a great first step to combat this issue, as it maintains a consistent temperature. But don’t stop there! Try using a heated bed and consider applying some adhesive to help your print stick better. And remember, patience is key. Rushing a 3D print job is like trying to speed up a soufflé; it usually doesn’t end well.

ABS vs. PLA: The Great Debate

In the world of 3D printing materials, the ABS vs. PLA debate is akin to the Coke vs. Pepsi showdown. PLA is fantastic for beginners due to its ease of use and lower printing temperature. However, if you need something that can take a beating and resist heat, ABS is your material of choice. ABS is better suited for industrial 3D printing and professional 3D printing jobs where strength matters. PLA might be easier to print with, but ABS is like the Rocky Balboa of 3D printing materials—a little rough around the edges but resilient and tough.

Choosing the Best ABS 3D Printer

When shopping for a 3D printer specifically for ABS, you want to look for models that can handle the high temperatures and provide a stable environment. An enclosed 3D printer is almost non-negotiable if you want to avoid the dreaded warp. Some of the best ABS 3D printers come with features like heated beds, precision printing capabilities, and advanced settings for controlling temperature and speed. Think of it as investing in a good pair of running shoes; you want something that fits well and can go the distance.

ABS Printing Tips for Success

- Temperature Control: Maintain a consistent high temperature for both the nozzle and the build plate.

- Use an Enclosed Printer: This helps keep the temperature steady and limits exposure to drafts.

- Apply Adhesive: Use some painter’s tape or a glue stick on the build plate to help the print adhere better.

- Take it Slow: Slower print speeds often lead to better results with ABS.

- Practice Makes Perfect: Don’t get discouraged by initial failures; each attempt is a learning opportunity.

Advanced and Professional 3D Printing

For those looking to take their 3D printing game to the next level, advanced 3D printing techniques can really shine with ABS. The material’s resilience makes it suitable for producing engineering-grade plastics that are perfect for DIY 3D printing projects or professional prototypes. Whether you’re crafting a complex part for a machinery prototype or creating a durable custom gadget, ABS is a reliable choice. And should you need to ensure the precision of your printed parts, a handy 3D scanner can be invaluable for quality control, checking dimensions down to the micron.

The Role of Industrial 3D Printing

In an industrial setting, ABS is often the material of choice for producing parts that need to be robust and reliable. This is especially true in sectors like automotive, aerospace, and consumer electronics, where parts not only need to look good but also function under stress. Industrial 3D printing with ABS allows for the creation of prototypes and final parts that are both functional and aesthetically pleasing. The ability to print in-house also speeds up the development process, making it a win-win situation.

DIY 3D Printing: Unleash Your Inner Maker

If you’re a DIY enthusiast, ABS gives you the flexibility to create a wide range of projects. From custom phone cases to parts for your model airplane, the possibilities are endless. The key is to have fun and experiment. Sure, you might end up with a few failed prints along the way, but that’s all part of the learning curve. Plus, nothing beats the satisfaction of holding a perfectly printed ABS object that you brought to life with your own two hands.

So, whether you’re in it for the fun or the functionality, ABS 3D printing offers a world of possibilities. With the right tools and a bit of patience, you can create durable, heat-resistant prints that stand the test of time. And who knows? You might just invent the next big thing in your garage. Just don’t forget to keep your printer enclosed and your sense of humor intact. After all, 3D printing is as much about the journey as it is about the destination.