Imagine a world where a house can be printed in a matter of days, where the walls are as customizable as a new smartphone case, and where Mother Earth gives an approving nod because we’re finally using eco-friendly materials. Welcome to the era of 3D printing in construction! This isn’t some sci-fi fantasy; it’s happening right now. And it’s as exciting as finding a $20 bill in an old jacket pocket.

3D Printing Construction: Building the Future, One Layer at a Time

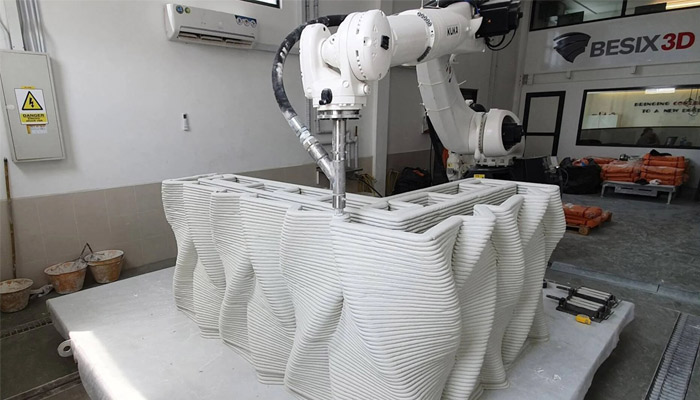

The construction industry is undergoing a seismic shift, thanks to 3D printing, also known as additive manufacturing. Forget about traditional brick-and-mortar methods. We’re talking about pushing a button and watching a printer lay down layer upon layer of material to create anything from a simple wall to a complex architectural marvel. It’s like playing with LEGO bricks, but on a grander, more sophisticated scale.

Concrete 3D printing is at the forefront of this revolution. This technique uses a specially formulated concrete mix that can be extruded layer by layer to form robust structures. It’s as if a giant toothpaste tube is squeezing out a building instead of minty freshness. The precision and speed are remarkable, leading to rapid construction timelines that leave traditional methods in the dust.

Sustainable Architecture: Because the Planet Deserves a Break

3D printing is not just about speed and efficiency; it’s also about sustainability. In an age where climate change headlines are as frequent as cat videos on the internet, sustainable architecture is not just a trend—it’s a necessity. Additive manufacturing significantly reduces waste. Think of it as baking a cake; you only use the ingredients you need, without any leftover batter. In construction, this translates to fewer resources wasted and a smaller carbon footprint.

Moreover, eco-friendly materials such as recycled plastics and biodegradable composites are making their way into 3D printed homes. It’s like giving the Earth a much-needed spa day. By using these materials, we’re not just building homes; we’re building a better future.

Smart Building Technology: Your Home but Smarter

3D printing is not just about the physical structure; it’s about integrating smart building technology right from the get-go. Picture this: a house that knows when to dim the lights, adjust the thermostat, and even order your groceries. While traditional homes can be retrofitted with smart tech, 3D printed homes can have these systems incorporated during the construction process.

It’s like upgrading from a dial-up modem to fiber optic internet. The potential for creating smart, interconnected homes is limitless, offering convenience, efficiency, and security. Your home is no longer just a shelter; it’s a partner in your daily life.

Cost-Effective Building: More Bang for Your Buck

One of the most exciting aspects of 3D printing in construction is its cost-effectiveness. Traditional construction methods are not only time-consuming but also expensive. From labor costs to material expenses, building a house can feel like burning a hole in your wallet.

Enter 3D printing, where costs are slashed thanks to reduced labor and material waste. It’s like buying a designer outfit at a thrift store price. By automating much of the construction process, labor costs are minimized, and the precision of additive manufacturing ensures that materials are used efficiently.

Benefits of Cost-Effective 3D Printing in Construction:

- Reduced labor costs due to automation

- Minimized material waste

- Faster construction timelines leading to lower financing costs

- Potential for customizable designs without significant price increases

Large-Scale 3D Printing: Thinking Big

While the concept of 3D printing often brings to mind small-scale projects, the technology is scaling up quickly. We’re not just talking about tiny houses or single-room structures. Large-scale 3D printing is making it possible to create entire neighborhoods in record time. Imagine a future where housing crises are addressed with the efficiency of printing a document. It’s not just an idea; it’s becoming a reality.

With the advancements in robotics and digital fabrication, the potential to print larger, more complex structures is expanding. These innovations are paving the way for a new era in architectural innovation, where the limitations of traditional construction are being shattered like a piñata at a birthday party.

Prefabricated Structures: Assembly Required, but Easier

Prefabricated structures have been around for a while, but 3D printing takes them to the next level. Instead of assembling pre-made parts like a giant IKEA project, 3D printing allows for the creation of bespoke components tailored to specific architectural designs.

This approach not only speeds up the construction process but also allows for greater customization. It’s like having a custom-made suit versus one off the rack. The efficiency and flexibility of 3D printed prefabricated structures make them an attractive option for developers and homeowners alike.

Robotics in Construction: Rise of the Machines

The integration of robotics in construction is no longer the stuff of futuristic movies. With 3D printing, robotics plays a crucial role in automating various processes, from mixing materials to extruding them in precise patterns. It’s like having a team of tireless workers who never need a coffee break.

These robotic systems are enhancing the speed, accuracy, and safety of construction projects. By reducing the need for manual labor, they also minimize the risk of accidents on site. It’s a win-win situation, where technology not only improves efficiency but also ensures the well-being of workers.

Innovative Construction Methods: Rethinking the Norm

3D printing is pushing the boundaries of what’s possible in construction. Innovative methods are emerging that challenge traditional norms and inspire creativity. Architects and engineers are exploring new forms, materials, and techniques that were previously unimaginable.

From curvilinear walls to intricate lattice structures, 3D printing allows for architectural innovation that is as functional as it is aesthetically pleasing. It’s like giving artists a new medium to express their creativity, resulting in buildings that are not only shelters but also works of art.

Eco-Friendly Materials: Building with a Conscience

One of the most compelling aspects of 3D printing in construction is the use of eco-friendly materials. As we become more conscious of our environmental impact, finding sustainable building materials has become a priority. Luckily, 3D printing offers a multitude of options.

From recycled plastics to biodegradable composites, these materials reduce the environmental footprint of construction projects. It’s like swapping out single-use plastics for reusable ones—better for the planet and for future generations. By embracing these materials, the construction industry is taking significant strides towards a more sustainable future.

In conclusion, 3D printing in construction is more than just a technological marvel; it’s a paradigm shift in how we think about building, sustainability, and housing. As additive manufacturing continues to evolve, the possibilities are endless. So, the next time you hear about a 3D printed house, remember that it’s not just a structure—it’s a glimpse into a future where innovation and sustainability go hand in hand. And who knows, maybe one day, you’ll be living in a home that was printed just for you, complete with all the bells and whistles. Now, that’s something worth printing out and framing!